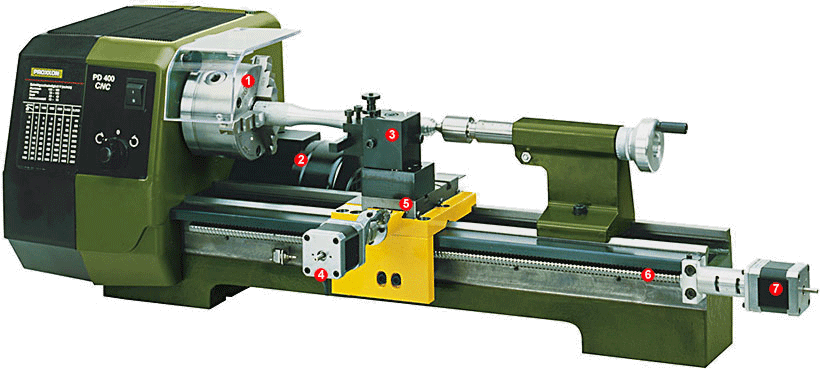

Precision lathe PD 400/CNC

Z-axis and X-axis with recirculating ball spindles and two powerful step motors.

Control unit for connecting to PC or laptop with activation of the main spindle and the step motors.

Including user-friendly and WINDOWS® compatible software (see description below).

CNC control of Z-axis and X-axis enables precise turning, facing and longitudinal turning of steel and non-ferrous metal.

1- Precision 3-jaw lathe chuck as per DIN 6386 (Ø 100mm).

2- Powerful condenser motor with 550W.

3- Multiple steel holder with height-adjustable holder elements.

4- Step motor 1.8A for travel distance 70mm.

5- Recirculating ball spindle for the X-axis with 2.0mm inclination.

6- Recirculating ball spindle for the Z-axis with 4mm inclination.

7- Step motor 1.8A for travel distance 300mm.

Axes drive with powerful step motors and recirculating ball spindles (no backlash). For facing and longitudinal turning, for turning balls, radii and any freely formed contours made of steel and non-ferrous metal. Work piece machining is effected automatically by software and can be reproduced as often as required.

Otherwise the mechanical design is almost identical to the proven PROXXON lathe PD 400: Solid, cross-braced cast iron bed with ground and wide legged prism guide for apron and tailstock ensure vibration-free working and optimum precision. High quality 3-jaw lathe chuck (Ø 100mm). 6 spindle speeds (80 - 2,800/min) are provided via belt drive. Including rotating centre MK 2 and tailstock chuck. With quick-change tool post with 2 holders (with stop and height adjustability).

Complete with recirculating ball spindles, powerful step motors and the required limit switches, the CNC control unit, all necessary connecting cables and WINDOWS® compatible software on CD-ROM.

View in Proxxon website