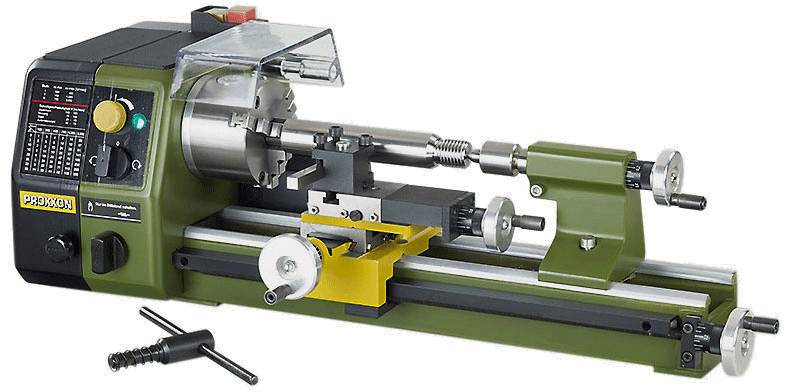

Precision lathe PD 250/E

For face, longitudinal and taper turning, thread-cutting.

For machining steel, brass, aluminium and plastic.

Mounting flange for fastening the mill/drill head PF 230.

Centre distance 250mm. Swing 70mm. Height over cross slide 43mm.

Machine bed: Of cast iron, wide-legged prismatic guide. For vibration-free work even at high loads. Rear flange for mounting the mill/drill head PF 230. Covered lead spindle.

Headstock: Of die-cast aluminium. Precision bearing mounted main spindle (run-out without chuck 1/100mm) with 10.5mm opening. Chuck side 70mm hollowed to 14mm. With MK 2 bore. Rotary switch for engaging the automatic feed via lead and feed spindle (optionally 0.05 or 0.1mm/rev.).

Tailstock: Of die-cast aluminium. Sleeve Ø 20mm, retractable up to 30mm. With millimetre scale, MK 1 bore and live centre.

Support: Bed carriage made of die-cast zinc. Cross slide and top slide of steel (adjustment 60 or 45mm). Turning tool post for cutting tools size 8 x 8mm.

Drive: Quiet DC special motor with 3-stage belt drive for 300 - 900 and 3,000rpm. With additional speed control (full-wave electronics) continuously adjustable to 100 - 300 or 1,000rpm, depending on belt ratio.

Clockwise - anticlockwise rotation. Main switch with emergency stop function and restart protection.

Lathe chuck: High quality 3-jaw chuck as per DIN 8386 Class 1 (concentricity tolerance 0.04mm). Capacity through reversing jaws from 2 - 75mm. Including lathe chuck guard with safety shutdown.

Handwheels: Of aluminium, with adjustable scale ring (1 division = 0.05mm, 1 revolution = 1mm).

Thread cutting device: With change gears for left-hand and righthand threads of the most important metric pitches (0.5 - 0.625 - 0.7 - 0.75 - 0.8 - 1 - 1.25 - 1.5mm).

Other technical data: 230V. 50/60Hz. Size L 560, W 270, H 170mm. Weight approx. 12kg.

View in Proxxon website