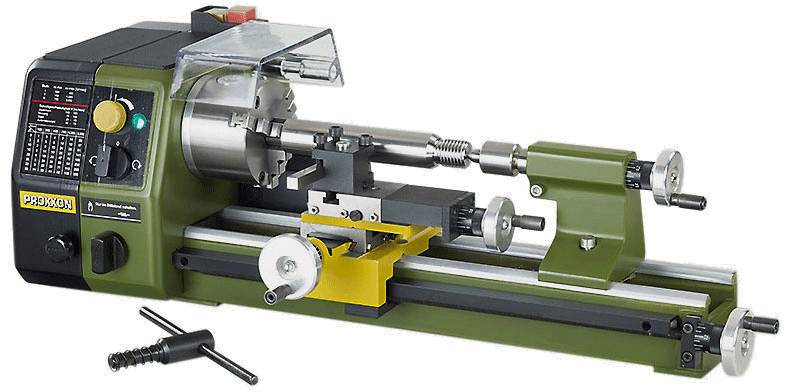

Precision lathe PD 400

Centre distance 400mm. Swing 85mm. Height over cross slide 58mm. For machining steel, brass, aluminium and plastic. For face and straight turning, taper turning and thread cutting. With an extensive range of system accessories you can also drill, mill and slot.

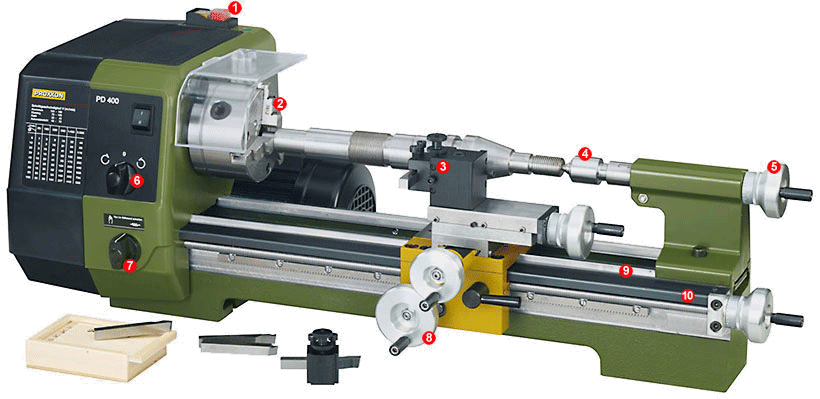

1- Main switch with auto-start protection and emergency off.

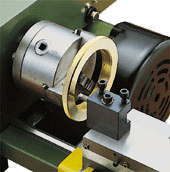

2- Precision lathe chuck as per DIN 6386 (Ø 100mm).

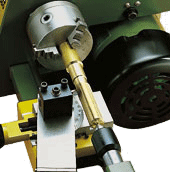

3- Quick-change tool post with 2 holders (with stop and height adjustability).

4- With rotating centre MK 2 and tailstock chuck.

5- Aluminium handwheels with adjustable graduated collar made from steel.

6- Switch for clockwise, off and counter-clockwise rotation.

7- Selector for auto-feed.

8- Quick-change tool post with 2 holders (with stop and height adjustability).

9- Cross-braced cast iron bed, wide-legged shape, and prism slides for apron and tailstock.

10- Protected lead screw with 12 x 1.5 Acme thread.

Machine bed: Of high quality cross-braced cast iron with wide-legged, prism slides. For vibration-free work even at high loads. With flange and threaded holes at back for fastening the drill and mill head PF 400. Covered lead spindle.

Headstock: Of die-cast aluminium. Oversized main spindle with two adjustable taper roller bearings and MK 3 bore on chuck side. Spindle bore 20.5mm. Run-out without chuck 1/100mm. Rotary switch for engaging the automatic feed (optionally 0.07 and 0.14mm/rev.). Lead and feed spindle with trapezoid threading (12 x 1.5mm).

Tailstock: Of die-cast aluminium. Sleeve Ø 24mm, retractable up to 40mm. With mm scale. With live centre MK 2 and 10mm gear tooth chuck (B 12 - bore/MK 2).

Support: Bed carriage made of die-cast zinc. Cross slide (adjustment 85mm) and top slide (setting range 52mm) of steel. Top slide can be swivelled for taper turning (degree graduation up to 45° available). With multiple tool posts and two tool post elements for quick change and easy height adjustment. For turning tools 10 x 10mm.

Drive: Powerful capacitor motor for two speeds and additional threestage belt drive. Spindle speeds at stage 1: 80 - 330 - 1,400rpm. For stage 2: 160 - 660 and 2,800rpm.

Lathe chuck: High quality 3-jaw chuck as per DIN 6386 Class 1 (concentricity tolerance 0.04mm). Capacity through reversing chucks 3 - 100mm. Including lathe chuck guard with safety shutdown.

Handwheels: Of aluminium, with scale ring adjustable to 0. For cross slide and top slide: 1 division = 0.025mm. 1 rev. = 1mm. For tailstock and lead spindle: 1 graduation line = 0.05mm. 1 rev. = 1.5mm.

Support quick adjustment: By means of large handwheel fastened to bed by toothed rack.

Thread cutting device: For left-hand and right-hand thread. With change gears for 19 different metric pitches: 0.2 - 0.25 - 0.3 - 0.35 - 0.4 - 0.45 - 0.5 - 0.6 - 0.7 - 0.75 - 0.8 - 0.9 - 1 - 1.25 - 1.5 - 1.75 - 2 - 2.5 - 3mm. Also for inch threads from 10 - 48TPI.

Other technical data:

230V. 50/60Hz. Size L 900, W 400, H 300mm. Weight approx. 45kg. Motor rated input 870W, power output 550W, motor speeds 1,400 / 2,800rpm.

A tool holder with two adjustable inserts is included as standard.

View in Proxxon website