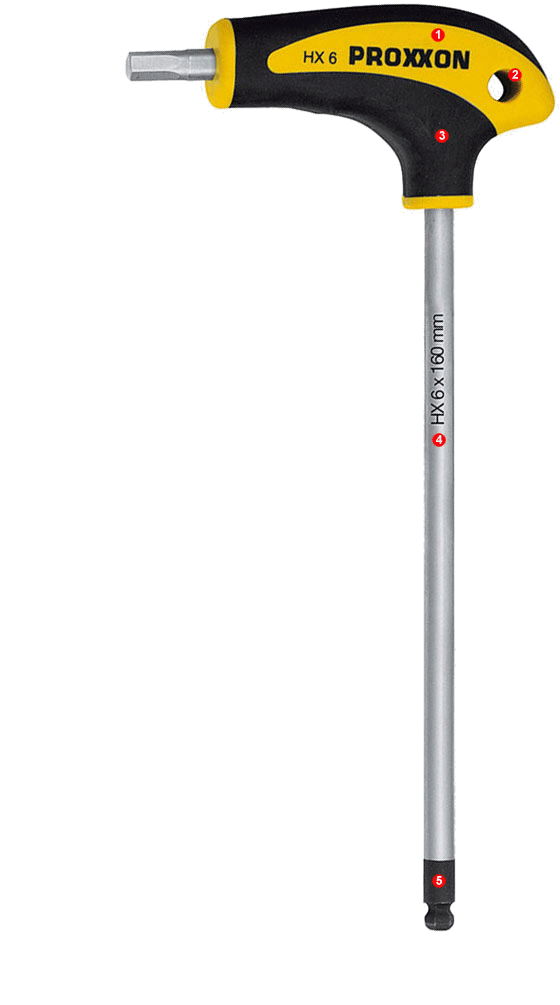

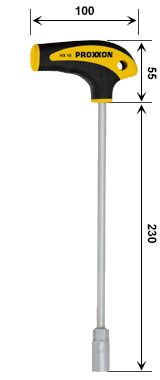

L-handle screwdrivers

1- Graded grip sizes correspond with the necessary torque of the respective blade size.

2- With transverse hole for hanging up.

3- Oil and acid-resistant non-stick special rubber handle.

4- Easy to read sizes through laser marking process on matte-chrome plated shafts of chrome silicon manganese molybdenum alloy special steel. Continuously hardened and stress-relieved with a balanced ratio of torsional rigidity and toughness.

5- Processed black tip for greatest precision for accepting screws. Also prevents tool from slipping.

If high torques are required for tightening or loosening screws, the L-handle screwdriver is the solution. The ergonomic and asymmetrical grip simplifies handling under continuous operation. Its two-component design with soft zones reduces pressure marks while at the same time allowing for optimum torque transfer. Easy-to-read sizes on shaft (laser marking) and handle.

Difficult to access

Allen screws can be screwed

at a working angle of

up to 25° with HX Ball.

When using the screw

socket of the short blade,

the longer shank is used

as "lever" for extreme torque.

L-handle HX screwdrivers

Short blade with sturdy standard HX, long blade with HX Ball (ball head).

L-handle TX screwdrivers

Short blade with sturdy standard TX, long blade with Tamper TX (with frontal hole).

L-handle HX nut screwdrivers

Optimum blade lengths for working on motors and all kinds of machines. Flats on HX nut allow for use of an open-end spanner to effortlessly loosen tightly locked screws.

View in Proxxon website