Mill/drill system BFW 40/E, with controller for speeds of 900 - 6,000rpm.

The triple ball bearing armature provides direct drive (no gearing).

Die-cast aluminium head with spindle neck of 43mm (European standard). Large, easy to use switch with emergency function. Chart indicates optimum speeds for milling and drilling of various materials.

The motor operates at 40V, supplied from the power pack/ controller. At this level, the control characteristics are ideal and yield high torque, even at lower speeds. (The compound table, drill stand and step clamps are not included.)

Other technical data:

Control unit with full wave electronics for 230V, 40VDC secondary voltage. Power consumption up to max. 250W. Spindle speed infinitely variable between 900 and 6,000rpm. Complete with triple slit, hardened collets covering 2.35 - 3 - 3.2 - 4 - 5 and 6mm as well as 2 spanners.

NO 20 165

Note:

The BFW 40/E is shown here as a tool combination with the mill/drill unit BFB 2000 and compound table KT 150. Neither tool is included.

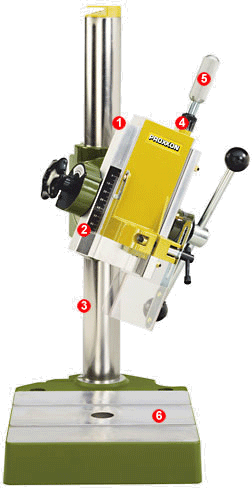

Mill/drill unit BFB 2000,

for standard drills

w ith 43mm spindle neck.

Head tilts through 90°, thus offering a multitude of capabilities: Diagonal drilling, versatile milling without need of special milling bits, milling of diagonal slots. Fine feed selectable allowing fine head feed for milling. With dial and depth scale. Geared rack and pinion feed for effortless drilling. 45mm diameter drill column, 500mm long. Approx. 140mm throat (column outside to tool centre). 65mm stroke. Plane-milled, solid base plate approx. 200 x 200mm with two continuous MICROMOT standard T-slots (12 x 6 x 5mm). Easy clamping of all common drills with standard 43mm spindle collar. Weight approx. 6.5kg.

NO 20 000

1- Milled, adjustable dovetail slide.

2- Clear, easily legible depth scale.

3- 45mm diameter column, 500mm long.

4- Adjustable zero position for fine feed.

5- Selectable fine feed with lever.

6- Sturdy, plane-milled work table with 2 MICROMOT standard T-slots (12 x 6 x 5mm).

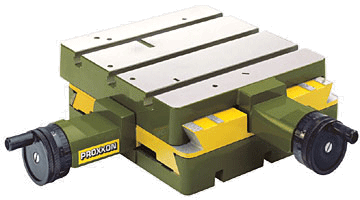

Die-cast aluminium compound table KT 150.

With precision milled dovetail slides, thus also suitable for metal work. For routing, milling, slotting of steel, non-ferrous metals, plastics and wood. Each slide provided with locking screws. With re-adjustable dovetail guides to eliminate play. Feed adjustment by means of 2 handwheels with graduated, zero-adjustable dials (1 revolution = 2mm feed, 1 graduation = 0.05mm feed). Plane-milled table. Three continuous MICROMOT standard T-slots (12 x 6 x 5mm). Fence with predrilled positioning holes, fastening screws. A practical screw clamp used when routing. Table 200 x 200mm. Maximum travel 150 x 150mm. Overall height 75mm. Weight 4.9kg.

NO 20 150

More accessories

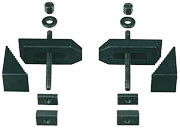

Milled steel step clamps

For MICROMOT standard T-slots (12 x 6 x 5mm). Two each step blocks and clamps with matching nuts and fixation screws. For work pieces up to a thickness of approx. 35mm. Neatly packed in wooden box with sliding lid.

NO 24 257

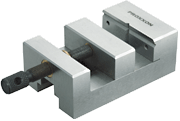

Precision vice PM 60

Perfectly rectangular. To be placed sideways and on the end face. With matching nuts and screws for fixation in MICROMOT standard T-slots (12 x 6 x 5mm). Supplied in wooden box with sliding lid.

Jaw width 60mm. Clamping capacity 42mm. Total length 100mm.

NO 24 255

Precision vice PRIMUS 75

Base body made of special cast iron with CNC-machined guides. Interchangeable gripping jaws. Flat-milled working surface. Spindles with rolled trapezoid thread for ease of operation even during high axial load. Width of jaws 75mm. Jaw opening 65mm. Distance from long slot centre to long slot centre 100mm. Long slots 80 x 11mm. Weight 2.5kg.

NO 20 392

Precision vice PRIMUS 100

Width of jaws 100mm. Jaw opening 75mm. Distance from long slot centre to long slot centre 135mm. Long slots 105 x 15mm. Weight 5.0kg. Other details as for the PRIMUS 75.

NO 20 402

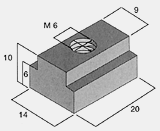

T-nut set for PRIMUS vices

2 T-nuts, screws and the necessary accessories. For fixing to the drill tables of: BFB 2000, KT 150 and bench drill press TBH.

NO 20 394

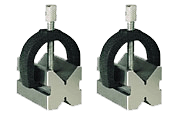

Precision V-blocks

Used to clamp various work pieces. Made from hardened steel, precision ground in pairs. Four different depths of prism incisions V, all at 90°. Size 50 x 30 x 30mm. The solid clamp and knurled knob ensure superb securing of the workpiece. Supplied in a wooden box with sliding lid.

NO 24 262 2 pieces

Milling cutter set (2 - 5mm)

All cutters with 6mm shaft. Cutters of Ø 2 - 3 - 4 and 5mm. Double fluted according to DIN 327. Made of HSS. Comes in wooden box with sliding lid.

NO 24 610

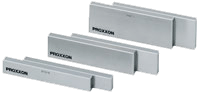

14-piece parallel supports set

Ground in pairs. For adjusting work on drilling machines, lathes and milling machines. Made of high-alloy, hardened steel (58 - 62 HRC). Parallel accuracy 0.002mm. 2 each of 8 x 10, 15, 20, 25, 30, 35 and 40mm. Length 100mm. Packed in a wooden box.

NO 24 266

View in Proxxon website